Polyether Ether Ketone

WHAT IS PEEK?

Polyether ether ketone (PEEK) is a colourless organic thermoplastic polymer in the polyaryletherketone (PAEK) family, used in engineering applications.

PEEK is a semicrystalline thermoplastic with excellent mechanical and chemical resistance properties that are retained to high temperatures. The processing conditions used to mould PEEK can influence the crystallinity, and hence the mechanical properties.

PEEK materials are commonly used in environments with hot water or steam, where they can maintain their physical properties, including flexural and tensile strength, at high levels. Although Polyetheretherketone is sometimes viewed as just an expensive engineering thermoplastic, experienced users recognise its true value. PEEK plastics offer exceptional material properties, enabling the production of lighter, more durable components that can endure tough operating conditions for extended periods.

The Young's modulus is 3.6 GPa and its tensile strength 90 to 100 MPa. PEEK has a glass transition temperature of around 143 °C (289 °F) and melts around 343 °C (662 °F). Some grades have a useful operating temperature of up to 250 °C (482 °F) . It is highly resistant to thermal degradation as well as attack by both organic and aqueous environments. It is attacked by halogens and strong acids as well as some halogenated compounds and aliphatic hydrocarbons at high temperatures. It dissolves completely in concentrated sulfuric acid at room temperature.

Because of its robustness, PEEK is used to fabricate items used in demanding applications, including bearings, piston parts, pumps, HPLC columns, compressor plate valves, and cable insulation. It is one of the few plastics compatible with ultra-high vacuum applications. It is extensively used in the aerospace, automotive, and chemical process industries.

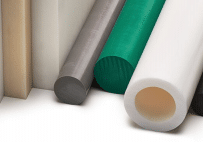

PEEK Product Shapes

Jade Metals produces PEEK thermoplastic as a standard semi-finished product for machining. The following shapes are possible:

- PEEK rod

- PEEK plate

- PEEK tube

Beneficial Properties of PEEK

- Good dimensional stability

- Superior Chemical resistance

- Superior wear & friction resistance

- High mechanical strength

- Superior resistance to gamma and X-rays

- High vacuum applications

Applications of Polyether Ether Ketone

- Nuclear environments

- Oil & Geothermal wells

- Chemical industries

- High pressure valves

- Food processing equipment

- High Vacuum plant

Why Choose Jade Metals?

To meet the unique processing requirements of your designed component, we offer a range of additional services, including cutting, planning, and grinding, which bring your part closer to its final size, saving both time and resources.

Jade Metals is one of the leading manufacturers of extruded PEEK semi-finished products, offering one of the most extensive product portfolios available. In addition to natural PEEK, we provide specialised grades for industries such as medical, semiconductor, electronics, and mechanical engineering. We also offer PEEK sheets, rods, and tubes in a broad range of sizes.