Mild Steel Supplier

Mild Steel 080A15, S355, EN8, EN36, EN40B

Order mild steel from Jade Metals today for high-quality, industry-standard materials. Our mild steel products offer excellent strength, ductility, and weldability, making them perfect for a wide range of applications, from construction to manufacturing. Whether you need sheets, bars, or custom solutions, we provide reliable and durable mild steel that meets your project requirements. With Jade Metals, you can expect fast delivery, superior customer service, and products that adhere to strict industry standards. To place your order today, give us a call and trust us to supply the best mild steel for your needs.

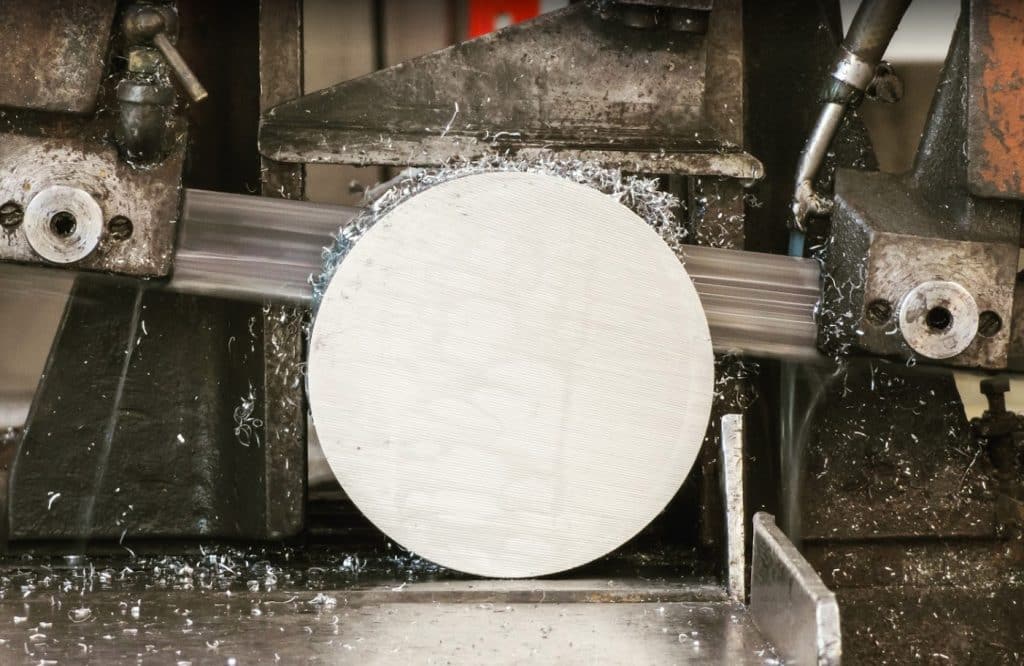

080A15 Mild Steel

This low carbon steel grade is supplied by Jade Metals Solutions as round and flat bars. Low carbon, unalloyed steel with the designation 080A15 is often sold as bright drawn bars. It is a bright mild steel of good grade for general engineering. Due to its low carbon content, this grade has excellent welding properties and is suitable for case hardening heat treatment.

S355 Mild Steel

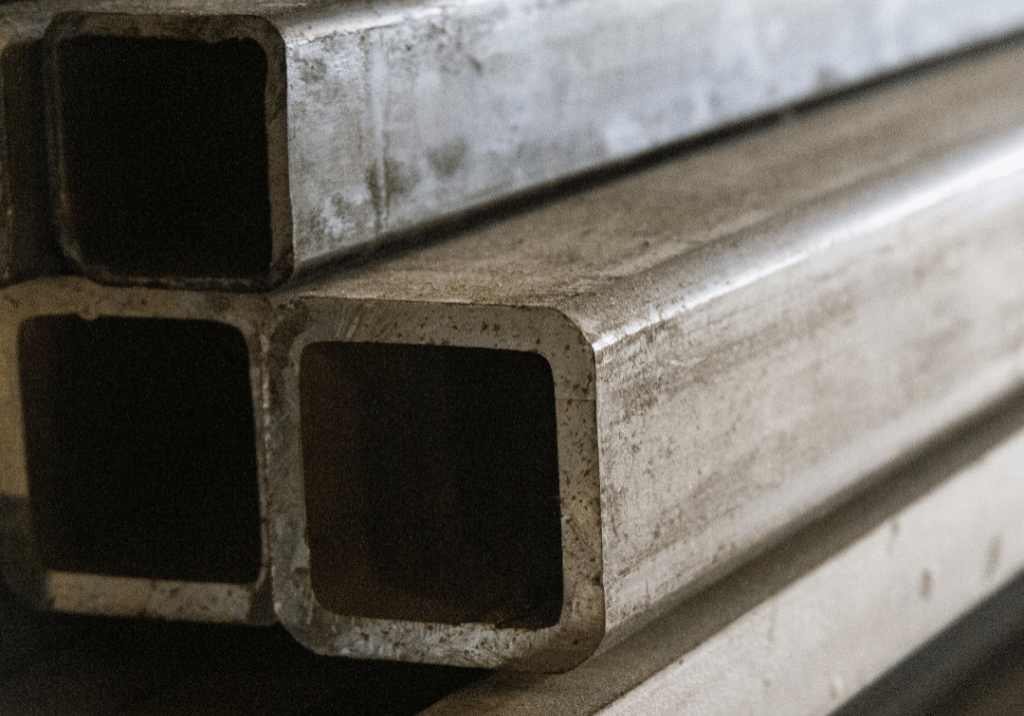

Various structural fabrication applications, such as bridge components, offshore structure components, power plants, mining and earth-moving equipment, load-handling equipment, and wind tower components, require high-strength non-alloy structural steel. Similar to ASTM A572 and ASTM A709 steel grades, S355 complies with European EN 10025:2004 structural steel standard. According to EN 10025 grade criteria, material grades (such as JR, JO, and K2) have different physical and chemical characteristics.

EN8 Mild Steel

A medium carbon steel called EN8 is unalloyed and utilised in applications where superior qualities than those of mild steel are required but where the expenses do not make the acquisition of a steel alloy financially viable. By using flame or induction hardening techniques, EN8 can be heat-treated to offer a good surface hardness and moderate wear resistance. EN8 is a well-known steel in the sector, used in anything from the automotive industry to more general engineering applications. Unalloyed carbon steel with a respectable tensile strength is EN8 engineering steel. It is a material that is easily machined and that can be flame- or induction-hardened. EN8 has a mediocre level of wear resistance when heat-treated.

EN36 Mild Steel

EN36 is a carburizing steel grade with a soft but strong core and extremely high surface strength. The substance nevertheless has a great amount of hardness. EN36, which has a high tensile strength, is utilised to make several high strength parts, including crankshafts for the automotive and aerospace industries. The high tensile strength and deep hardening of EN36 Engineering Steel are a result of the alloy's nickel and chrome composition. with exceptional fatigue resistance and hardness.

EN40B Mild Steel

EN40B is a chromium-molybdenum nitriding steel that may support high wear resistance due to its aptitude for nitriding. The material is offered in EN40B, which gives good hardness and good ductility, in the hardened and tempered 'T' state. Nitriding creates a surface that is distortion-free and free of scales. High wear resistance is offered by EN40B engineering steel. The alloy also has good toughness and ductility, as well as good shock resistance. The hardened and tempered "T" condition of EN40B is what is delivered. It is categorised as steel for nitriding.

Mild steel has limited corrosion resistance and can rust when exposed to moisture and oxygen. To enhance its durability, it is often coated with protective layers such as paint, galvanization (zinc coating), or other corrosion-resistant treatments.

Yes, mild steel is fully recyclable. Steel recycling involves melting down scrap steel and reprocessing it into new steel products, conserving natural resources and energy.

Mild steel is widely used in construction due to its high strength, ease of fabrication, and cost-effectiveness. It can be readily formed into structural shapes such as beams, columns, and plates, making it ideal for building frameworks and other structural components.