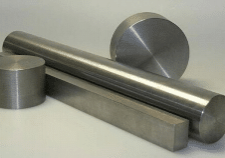

D2 Tool Steel

The group D steels, which are high-carbon, high-chromium steels, are used in cold-work tools. These are the D2, D3, D4, D5, and D7 steels, which are referred to as group D steels. These steels have 12% chromium and 1.5–2.35% carbon. All other group D steels are air hardened and contain 1% mo, with the exception of type D3 steel. Although small portions can be gas quenched using a vacuum following austenitization, Type D3 steel is oil-quenched. Because of this, type D3 steel tools often become brittle during the hardening process. Among group D steels, type D2 steel is the one that is utilised the most frequently.

Chemical Composition

The following table shows the chemical composition of D2 tool steels.

| Element | Content (%) |

| C | 1.40 – 1.60 |

| Mn | 0.60 |

| Si | 0.60 |

| Co | 1.00 |

| Cr | 11.00 – 13.00 |

| Mo | 0.70 – 1.20 |

| V | 1.10 |

| P | 0.03 |

| Ni | 0.30 |

| Cu | 0.25 |

| S | 0.03 |

Physical Properties

The physical properties of D2 tool steels are outlined in the following table.

| Properties | Metric | Imperial |

| Density | 7.7 x 1000 kg/m3 | 0.278 lb/in3 |

| Melting point | 1421°C | 2590°F |

Mechanical Properties

The mechanical properties of D2 tool steels are tabulated below:

| Mechanical Properties | Metric | Imperial |

| Hardness, Knoop (converted from Rockwell C hardness) | 769 | 769 |

| Hardness, Rockwell C | 62 | 62 |

| Hardness, Vickers | 748 | 748 |

| Izod impact unnotched | 77.0 J | 56.8 ft-lb |

| Poisson's ratio | 0.27-0.30 | 0.27-0.30 |

| Elastic modulus | 190-210 GPa | 27557-30457 ksi |