Engineering Plastic Supplier

The One Stop Metal and Plastic Shop

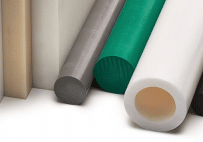

Order engineering plastic from Jade Metals today for high-performance, industry-standard materials. Our engineering plastics are known for their strength, lightweight properties, and resistance to chemicals and wear, making them ideal for a variety of industrial applications, including automotive, electronics, and manufacturing. Whether you need plastic sheets, rods, or custom parts, we provide reliable solutions designed to meet your project needs. With Jade Metals, you’ll receive fast service, excellent customer support, and top-quality products that adhere to industry standards. Call us to place your order today and let us supply the engineering plastics that ensure durability and efficiency in your applications.

Natural Acetal

An outstanding balance of tensile characteristics, shear strength, stiffness, and toughness can be found in acetal copolymers. The high tensile yield strength of this resin demonstrates how tough it is. Its extremely low coefficient of friction with metals and good abrasion resistance make it a suitable bearing material. The thermal characteristics are really good. It maintains its shape and physical integrity at high temperatures and has remarkable resilience to high intermittent temperatures. Outstanding long-term stability at high temperatures. Its strong ability to maintain the initial mechanical properties of hot air and hot water are further thermal qualities.

Natural Nylon

A family of synthetic polymers based on aliphatic or semi-aromatic polyamides are collectively referred to as nylon. Nylon is a smooth thermoplastic polymer that may be formed into fibres, films, or other shapes through melting. Similar to the peptide bonds in proteins, it is composed of repeated units connected by amide linkages. To create numerous distinct property modifications, a large range of additives can be blended with nylon polymers. Significantly useful commercial uses for nylon polymers include fabric and fibres (clothing, flooring, and rubber reinforcement), forms (moulded parts for cars, electrical equipment, etc.), and films (mostly for food packaging).

Polyether Ether Ketone (PEEK)

A semi-crystalline, high-performance engineering thermoplastic is polyetheretherketone (PEEK). This brittle opaque (grey) material has a distinctive blend of mechanical qualities, chemical resistance, wear resistance, fatigue resistance, creep resistance, and unusually high temperature resistance up to 260°C (480°F). This polymer is a member of the Polyketonefamily of Polymers (PEK, PEEK, PEEKK, PEKK, PEKEKK), of which PEEK is the most utilised and mass produced.

TUFNOL

A patented brand of laminated plastic material is called TUFNOL. It is one of the original forms of resin-bonded plastic materials used for engineering components, and it has been produced in Birmingham, England, since the mid-1920s.

Laminates are typically thought of as hard, thin sheets that are utilised for flooring, countertops in kitchens, and other applications.

It's "decorative laminates" in this case. An "industrial laminate" is TUFNOL. It's not created in thin sheets or with a surface layer that is specifically coloured or patterned, but it is made in large chunks that are utilised to make industrial and equipment parts. Depending on the quality, it can range in colour from brown to white and be produced in solid sheets up to 225mm (9 inches) in thickness, produced in round rods and tubes.

It is commonly used in automotive parts, electrical components, medical devices, and consumer goods like gears, bearings, and fasteners. It is commonly used in precision parts requiring high stiffness, low friction, and excellent dimensional stability.

Yes, Natural Nylon is relatively easy to machine using standard metalworking equipment, but it requires sharp tools and proper cooling to avoid overheating and distortion.

PEEK maintains its mechanical properties at high temperatures, making it suitable for applications that require long-term thermal stability. PEEK has excellent resistance to radiation, making it ideal for use in medical and nuclear applications.

Key properties include high mechanical strength, excellent electrical insulation, good wear resistance, and low moisture absorption.